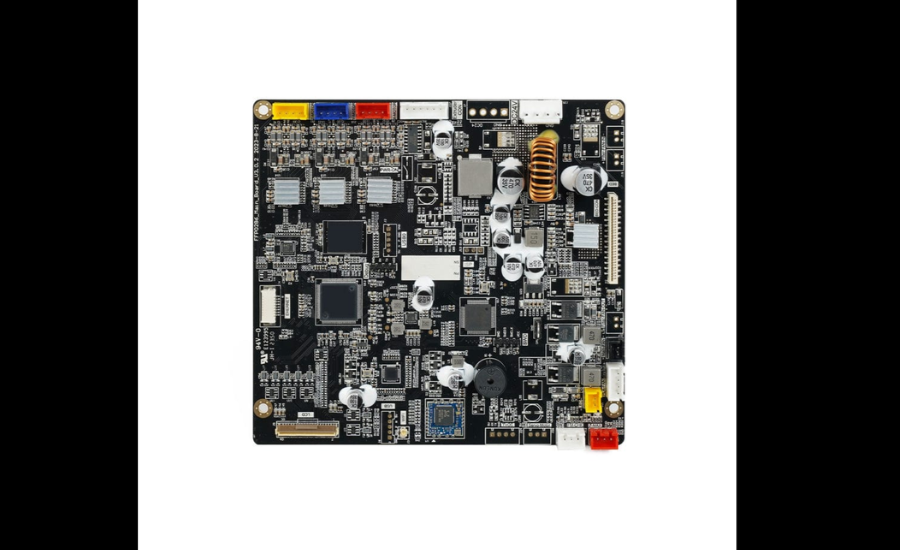

Pin out flashforge m5 main board When working with the Flashforge M5 3D printer, whether you’re upgrading components, troubleshooting, or experimenting with custom mods, knowing the mainboard pinout is essential. This guide breaks down the pinout of the Flashforge M5 mainboard in a straightforward and accessible way, designed for both experienced users and newcomers to 3D printer electronics.

By understanding the mainboard’s pinout, you can navigate your 3D printing projects with greater ease and precision. This insight into the essential connections within the printer’s system empowers you to make informed decisions, ensuring your printer operates smoothly and efficiently.

Key Connections on the pin out flashforge m5 main board

The Flashforge M5 mainboard features several essential connections that are critical for the printer’s efficient operation.

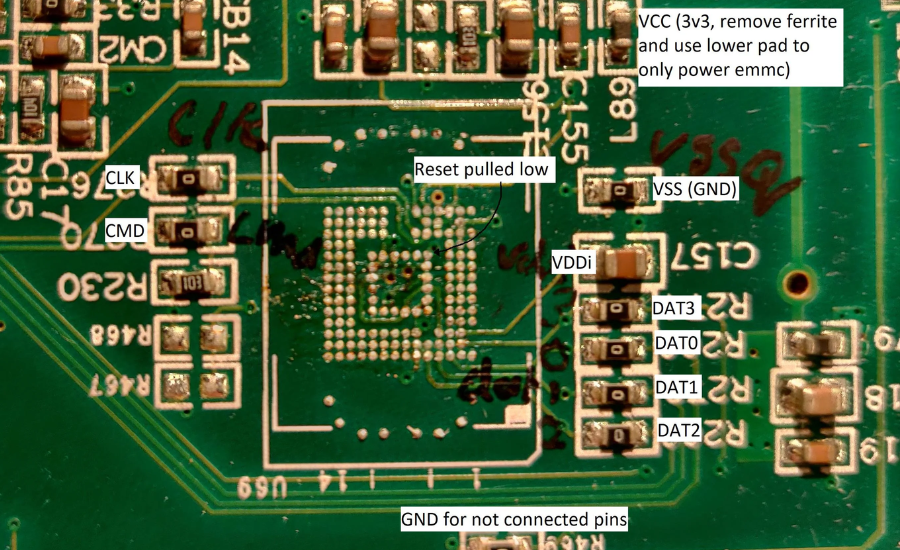

Power Input: Located on the edge of the board, these pins provide the 24V DC power required for the mainboard and its components to function properly.

Stepper Motor Connectors: Pins are dedicated to the X, Y, and Z motors, which control the movement of the print head and build plate, while the E motor drives the extruder. Proper alignment of these pins is crucial to avoid movement errors.

Endstop Pins: These connections link to limit switches or optical sensors, allowing the printer to detect when an axis reaches its limit (X_min, Y_min, Z_min).

Extruder and Heated Bed Connections: These pins regulate the heating of both the extruder nozzle and the build plate, ensuring the printer maintains the correct temperatures. Proper wiring is essential to prevent overheating or potential damage.

Thermistor Connections: These pins monitor the temperature of the extruder and heated bed. Ensuring compatibility with the specified thermistor type in your printer’s firmware is vital for accurate temperature readings.

The Importance of the Flashforge M5 Mainboard

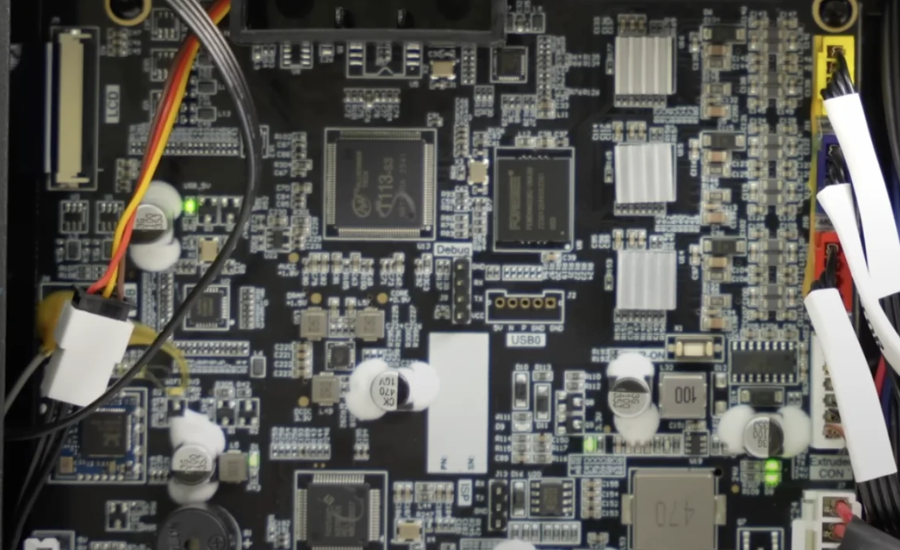

The mainboard, often referred to as the motherboard or control board, serves as the central hub of your 3D printer. It coordinates all the essential functions, ensuring seamless communication between critical components such as motors, the extruder, heated bed, sensors, and the display.

For the Flashforge M5, the mainboard is integral to its performance. Understanding its pinout diagram is crucial for a variety of tasks, from upgrading parts to installing custom firmware or resolving technical issues. A clear understanding of the mainboard layout not only streamlines these processes but also helps maintain optimal printer performance.

The Role of a Pin-Out Diagram

A pin-out diagram offers a comprehensive overview of the pin configuration on a circuit board, highlighting the specific function of each pin. Whether it’s powering a motor, relaying temperature information, or connecting different components, the diagram helps you identify the purpose of every connection. This understanding is crucial for tasks such as troubleshooting, upgrading components, or making custom modifications to your 3D printer. Familiarity with the pin-out not only ensures correct wiring but also empowers you to optimize and maintain your printer’s performance effectively.

Maximizing Performance with the Flashforge M5 Pin-Out

The Flashforge M5 mainboard is engineered for high-performance, precise 3D printing. A thorough understanding of its pin-out can greatly improve the printer’s functionality and contribute to its long-term upkeep.

By studying the pin-out, you gain insight into how each component connects to the mainboard, allowing for smoother integration of upgrades such as auto bed leveling or filament runout detection. This knowledge is also invaluable for maintenance, ensuring accurate connections after repairs and minimizing potential errors or downtime. Ultimately, mastering the pin-out enhances customizations, troubleshooting, and overall printer care, making for a more efficient and flexible 3D printing experience.

Maintaining the Flashforge M5: Best Practices

Proper handling and preparation are essential for maintaining the Flashforge M5’s performance during maintenance or upgrades.

Before disassembling any components, label the wires to ensure a smooth reassembly process. This simple step helps prevent connection errors when putting everything back together. After disconnecting the components, take the time to carefully verify each connection before powering the printer back on. This extra step can prevent potential damage or malfunctions caused by incorrect wiring.

For troubleshooting or guidance, refer to trusted resources such as the Flashforge manual or user forums, where you can find valuable tips specific to your model. When working with delicate components, always use appropriate tools like insulated tweezers to minimize the risk of accidental damage. By following these precautions, you can protect your printer and maintain its performance over time.

Troubleshooting the Flashforge M5

If your Flashforge M5 isn’t powering on, start by checking the power input pins to ensure all connections are secure. If the issue persists, use a multimeter to confirm that power is properly reaching the board.

For issues with motor movement, examine the stepper motor connectors. If the motors are moving incorrectly, try adjusting the connector orientation or tweaking the settings in the firmware.

Inaccurate temperature readings are often caused by faulty thermistor wiring. Double-check the connections, and if needed, replace the thermistor. Ensure that the firmware is configured to match the type of thermistor you have installed.

If there’s no display output, inspect the display cable for loose or improper connections. Reseat the cable securely, and if the problem continues, test the board with a compatible replacement screen.

By following these troubleshooting steps, you can quickly resolve common issues and maintain the smooth operation of your 3D printer.

Best Practices for Printer Maintenance

Before disassembling any components, make sure to clearly label the wires. This simple step ensures that reassembly will be quick and error-free, helping to avoid connection mistakes.

Once you’ve disconnected everything, take the time to carefully verify that all components are properly reconnected before powering the printer back on. This precaution helps prevent potential damage or malfunctions caused by incorrect wiring.

For any guidance or troubleshooting, refer to trusted sources like the Flashforge manual or online forums, where you can find helpful tips specific to your printer model.

When handling delicate parts, always use the right tools, such as insulated tweezers, to ensure safety and precision. This minimizes the risk of accidental damage and ensures the longevity of your printer.

Troubleshooting Common Printer Issues

If your printer fails to power on, start by inspecting the power input pins for any loose connections. Make sure the wires are securely attached, and if the issue persists, use a multimeter to verify that power is being delivered correctly to the board.

For issues with incorrect motor movement, check the stepper motor connectors. If the motors are running in the wrong direction, reversing the connector orientation or adjusting the firmware settings can often resolve the problem.

Inaccurate temperature readings are typically caused by faulty thermistor wiring. Double-check the wiring and replace the thermistor if necessary. Also, ensure the firmware settings are properly configured for the type of thermistor installed.

If the display is blank, examine the display cable for any loose or incorrect connections. Securely reseat the cable, and if the issue persists, try testing the board with a compatible replacement screen.

By following these steps, you can efficiently address common issues and keep your printer running smoothly.

Final Words

Understanding the pinout of the Flashforge M5 mainboard is crucial for anyone working with this 3D printer, whether for upgrades, troubleshooting, or custom modifications. The mainboard serves as the central hub, connecting key components such as motors, the extruder, heated bed, and sensors. Knowing the pinout layout allows for precise handling of these connections, ensuring smooth operation and preventing errors.

By familiarizing yourself with the pinout, you can effectively manage tasks like wiring upgrades, troubleshooting common issues, or performing maintenance. It also helps in integrating new features such as auto bed leveling or filament runout detection. Whether you’re upgrading parts or resolving technical issues, understanding the Flashforge M5 mainboard pinout ensures optimal performance and minimizes downtime, contributing to a more efficient 3D printing experience.

FAQs

1. What is the Flashforge M5 mainboard pinout?

The Flashforge M5 mainboard pinout refers to the layout of pins on the printer’s control board. Each pin serves a specific function, such as powering components, controlling motors, and monitoring temperatures. Understanding the pinout is essential for tasks like upgrading parts, troubleshooting, and making custom modifications.

2. How can I use the pinout to troubleshoot my Flashforge M5?

By understanding the pinout, you can quickly locate the connections responsible for various components. For example, if your printer isn’t powering on, check the power input pins. If motors aren’t moving correctly, inspect the stepper motor connectors. The pinout helps identify potential issues and guide repairs.

3. Why is the pinout important for upgrading the Flashforge M5?

The pinout provides a clear map of the mainboard’s connections, which is essential when upgrading or adding new components like auto bed leveling sensors or filament runout detection. Knowing where each component connects ensures a smooth upgrade process and helps maintain the printer’s performance.

4. How do I read the Flashforge M5 mainboard pinout diagram?

A pinout diagram shows the position and function of each pin on the mainboard. It typically labels the pins for power input, stepper motors, thermistors, endstops, and other critical components. By referring to the diagram, you can easily identify which pins control each part of your printer.

5. Can I modify the Flashforge M5 using the pinout?

Yes, understanding the pinout allows you to make custom modifications to your printer, such as adding new sensors, motors, or changing wiring configurations. However, ensure that any modifications are compatible with the mainboard to avoid damaging components or causing malfunctions.

6. What should I do if I make a mistake while connecting components to the mainboard?

If you make a mistake while connecting components, double-check the wiring against the pinout diagram. Make sure each connection is secure and properly aligned. If you encounter persistent issues, consider referring to the Flashforge manual or online forums for troubleshooting tips.

7. How do I maintain the Flashforge M5 mainboard?

Regular maintenance of the mainboard includes ensuring all connections are secure, cleaning the board from dust or debris, and verifying that components like the stepper motors, thermistors, and extruders are functioning correctly. Using the pinout as a reference, you can also check for any loose or damaged connections during routine maintenance.

8. Where can I find the Flashforge M5 mainboard pinout diagram?

You can find the pinout diagram in the printer’s user manual or by searching online for resources dedicated to Flashforge M5 modifications and repairs. Additionally, many 3D printing forums and communities share pinout diagrams and wiring guides for specific printer models.

For exclusive insights and updates, stay connected with Gravity Internetnet.